- SCHENCK TREBEL CORPORATION VERIFICATION

- SCHENCK TREBEL CORPORATION ISO

- SCHENCK TREBEL CORPORATION SERIES

SCHENCK TREBEL CORPORATION VERIFICATION

Prove it to your customers! If you wish to safeguard the quality of your production through periodic verification of your machines, contact us at the address below, or visit our website. Verification of the measurement uncertainty and issuing of a test certificate in accordance with the current DIN EN ISO/IEC 17025 standard.

SCHENCK TREBEL CORPORATION ISO

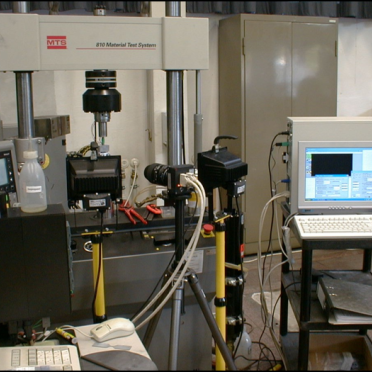

Verification of your balancing machines to ISO 2953 and internal test standards.Our test center will assist you in the documentation of the quality of your working processes and manufacturing equipment through competent Measuring equipment (Master/test rotors and weights).Low-speed horizontal balancing machines.In our testing center for balancing system – the first worldwide – we will use traceable methods to perform verification of the following: You will be able to benefit from our extensive knowhow. No other company can offer comparable experience and a broader knowledge base when it comes to testing of balancing machines. During this period, we have had a significant influence on balancing technology and left our mark through our long-standing participation in standards committees. Schenck has been manufacturing balancing machine for almost 100 years. Spin-testing of rotors weighing up to 400 kg at speeds up to 63,000 min -1.Determination of the moment of turbine and jet engine blades up to 2 kgm.Verification of master rotors (measuring equipment in accordance with DIN EN ISO 9001) and issuing of a test certificate to DIN EN 10204.Balancing of one-of-a-kind components and batches.Precision-balancing to highest accuracies.Balancing of flexible rotors at or near service speed using computer-assisted methods.With disc-shaped rotors, the maximum diameter is 4000 mm. Cylindrical rotors up to 7000 mm long and with a maximum diameter of 3400 mm can be balanced in our balancing center. Balancing of rotors weighing up to 20,000 kg on state-of-the-art balancing machines.This is what our balancing and spintesting service can do for you: Even problematic rotors can be handled quickly and difficult problems solved. Our trained staff have vast experience with efficient and precise balancing or spin-testing of any type of rotor.

We are happy to advise you, even with a commercial comparison of buying your own machine against using our service.

SCHENCK TREBEL CORPORATION SERIES

Production series and individual parts are brought up to the required unbalance tolerance, quickly and affordably.

Our modern service centers offer you a rotor balancing service. It isn’t always the most economical solution to have your own machine. Filling and Automation - DÜRR Somac (DSC)įax +48 (0) 32 780 67 Trebel Corporation.Assembly and Testing Systems - DÜRR Assembly Products (DAP).Transportable Balancing Machine For On Site Balancing.Vibration Accelerometer Triaxial Sensor SR 173.Velocity- Loop Powered Sensor – SR LPS 420.Transportable Balancing Machine For On Site BalancingĪssembly and Testing Systems - DÜRR Assembly Products (DAP)įilling and Automation - DÜRR Somac (DSC) Vibration Accelerometer Triaxial Sensor SR 173 Velocity- Loop Powered Sensor – SR LPS 420

0 kommentar(er)

0 kommentar(er)